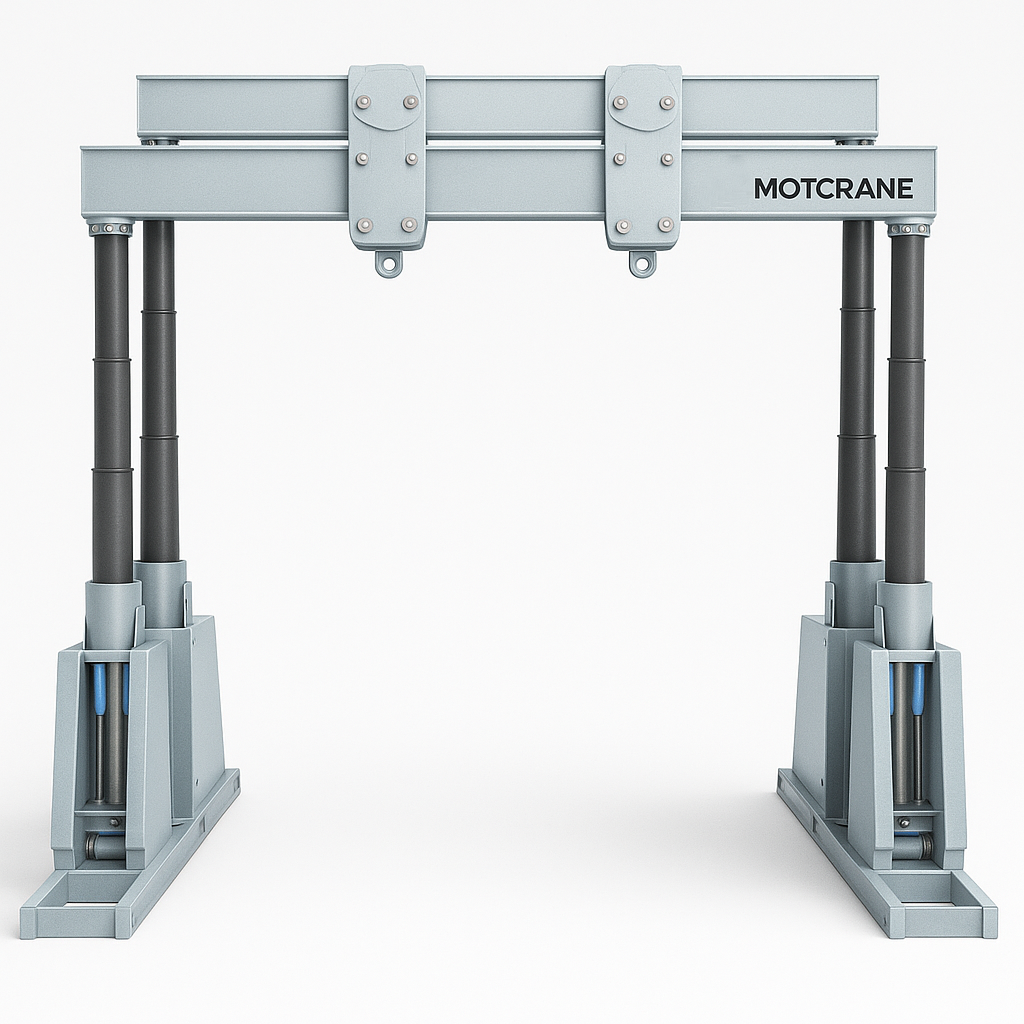

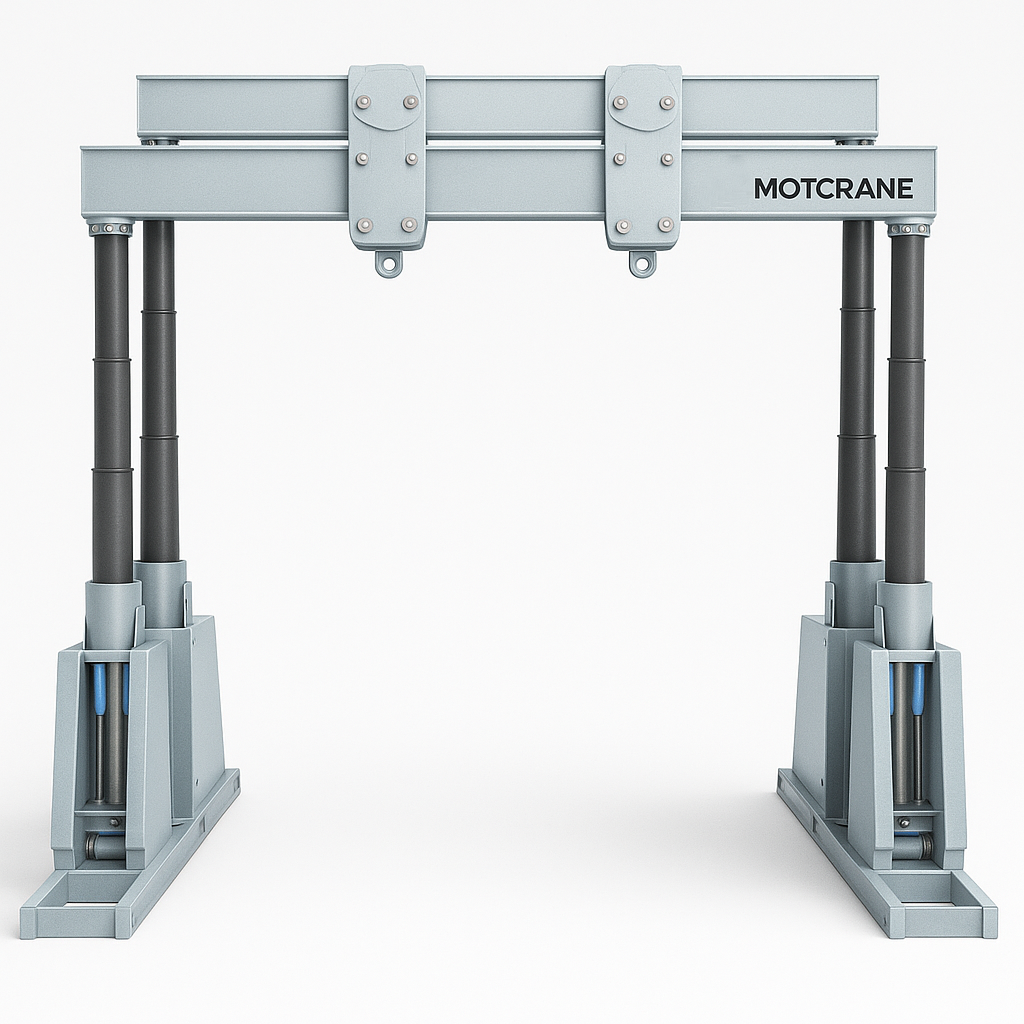

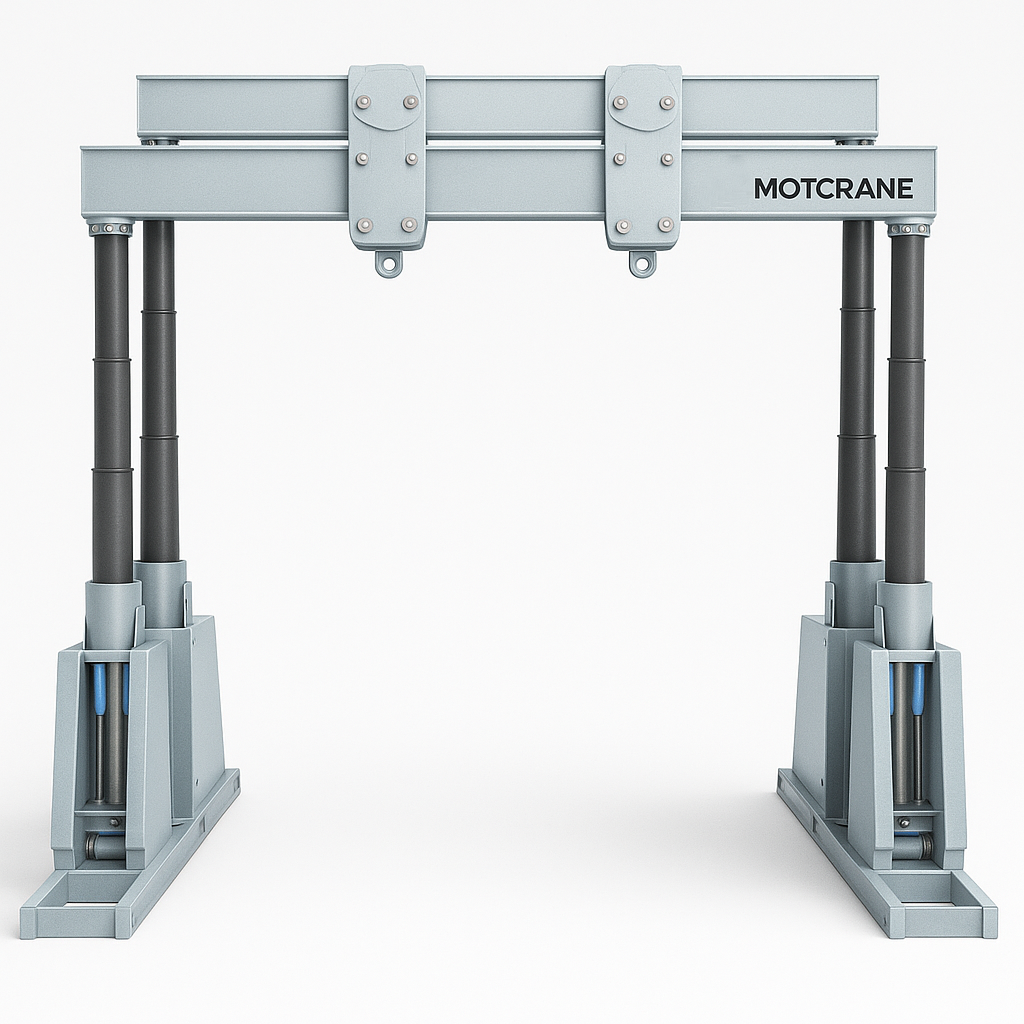

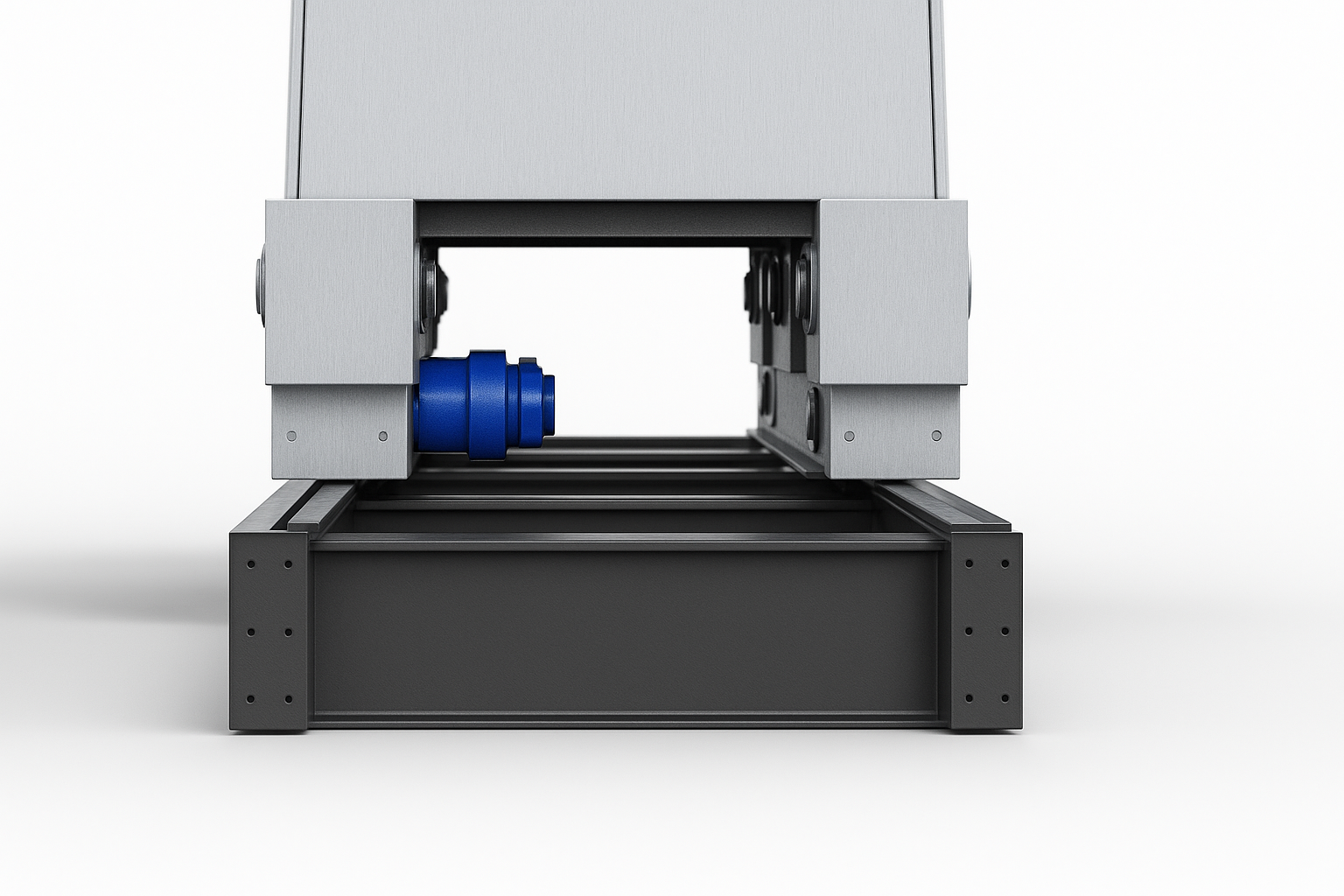

Hydraulic gantry crane, mainly used for lifting and assembling large equipment (20t-1100t). The crane adopts a modular structural design, which facilitates the assembly, disassembly, and transfer work of the crane. The crane has a compact structure, which is suitable for both small space and outdoor use. Compared to conventional roll style bridge cranes, hydraulic gantry cranes operate more smoothly and have higher lifting and operating accuracy.

| ♦ Capacity(4 legs): | 20t~1100t |

| ♦ Header beams: | 6m/8m/10m/12m |

| ♦ Lifting Height: | 3m~12m |

| ♦ Control mode: | Wireless remote control |

| ♦ Protection class: | IP54/IP55 |

| ♦ Power Source: | 3P 380V 50HZ or others |

| ♦ Working temperature: | -20℃ to 45℃ |

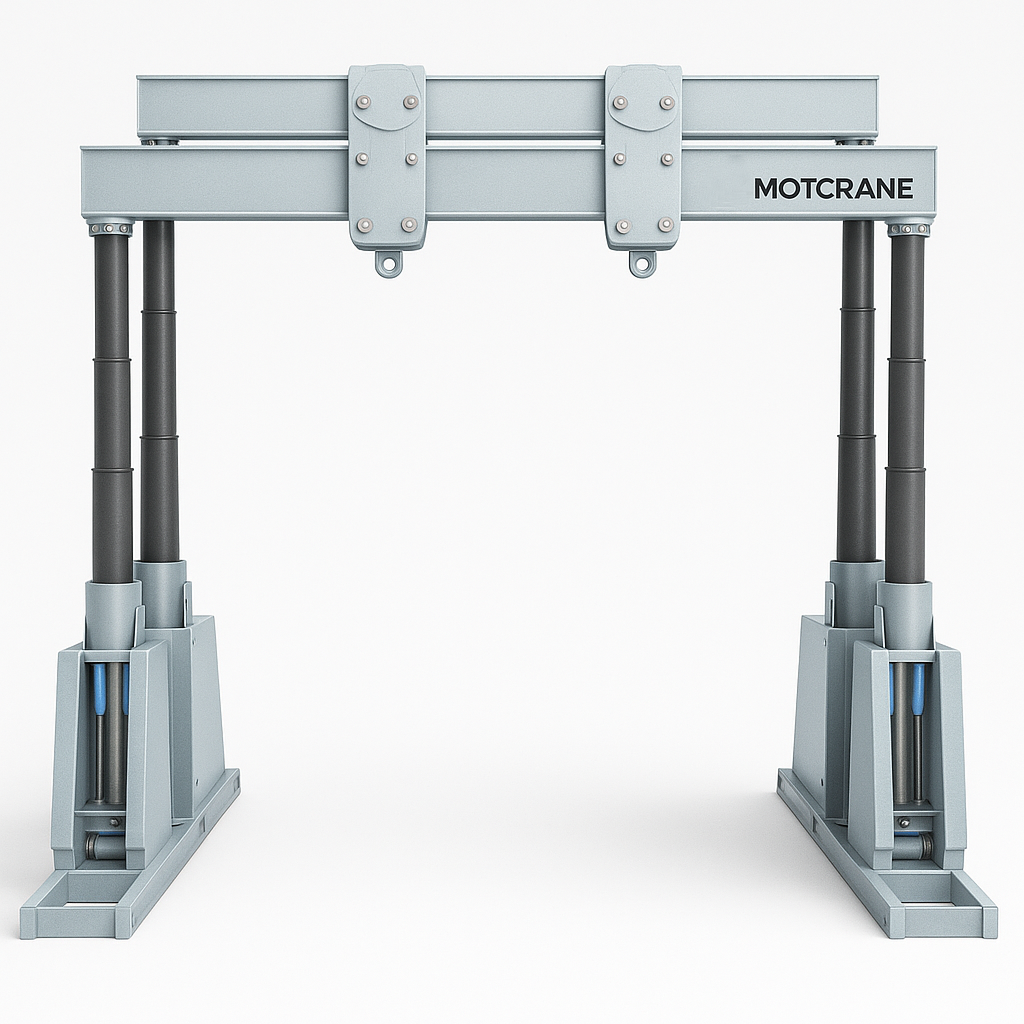

| Compact and cost-effective gantry with best-in-class controls |

| Load Capacity:20t-100t |

| Lifting Height:≤10m |

| Retracted Height:≥2m |

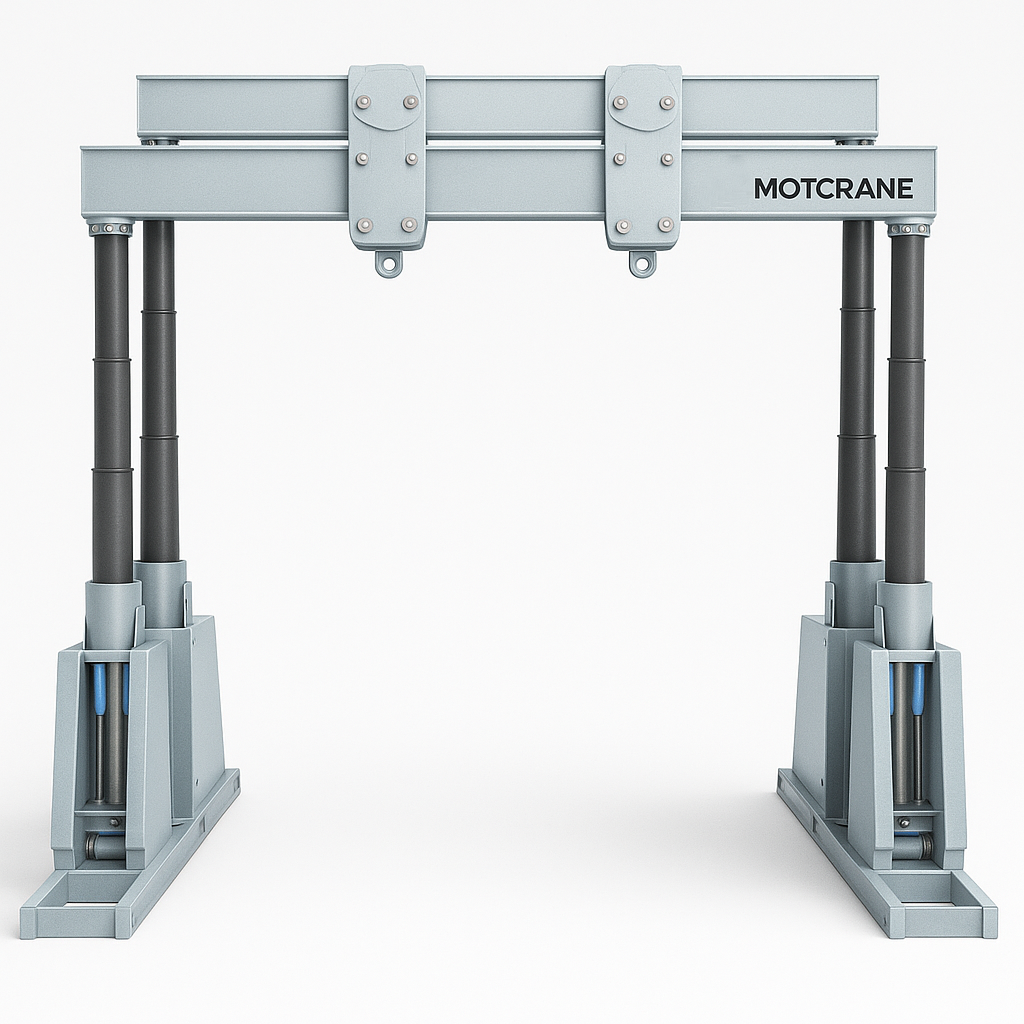

| Cost-effective gantries with best-in-class controls and up to 450 ton capacity |

| Load Capacity:120t-450t |

| Lifting Height:≤12m |

| Retracted Height:≥3m |

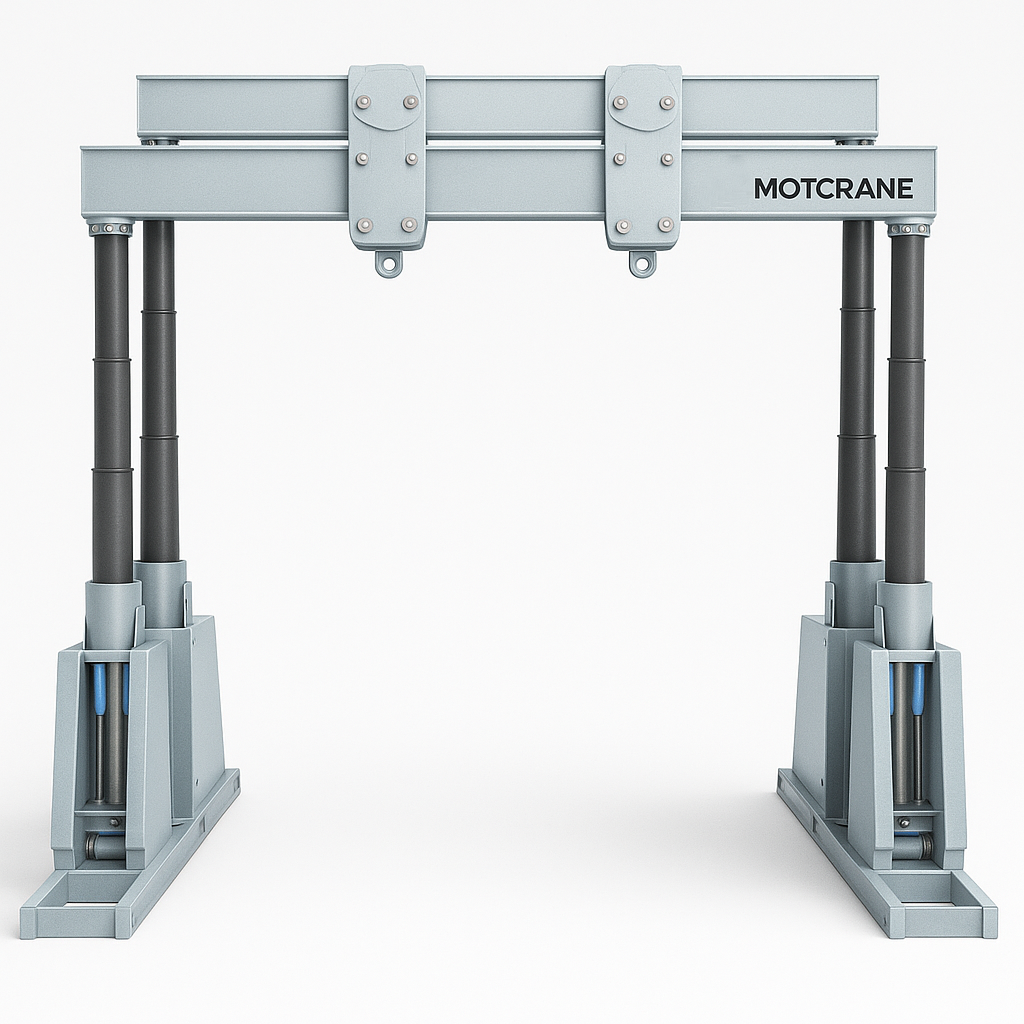

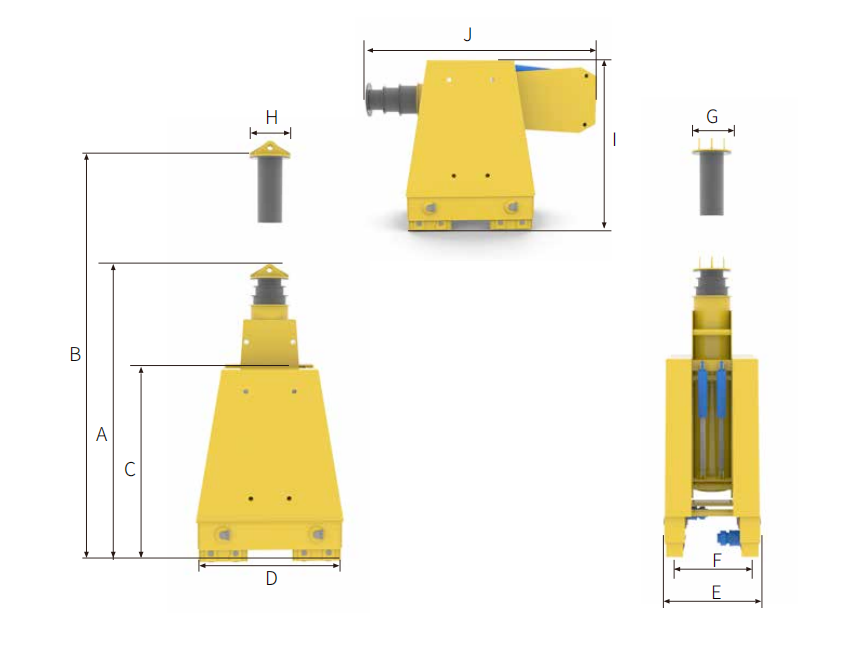

| Heavy duty, boom style gantries with best-in-class controls and up to 1100 ton |

| Load Capacity:500t-1100t |

| Lifting Height:≤12m |

| Retracted Height:≥3.5m |

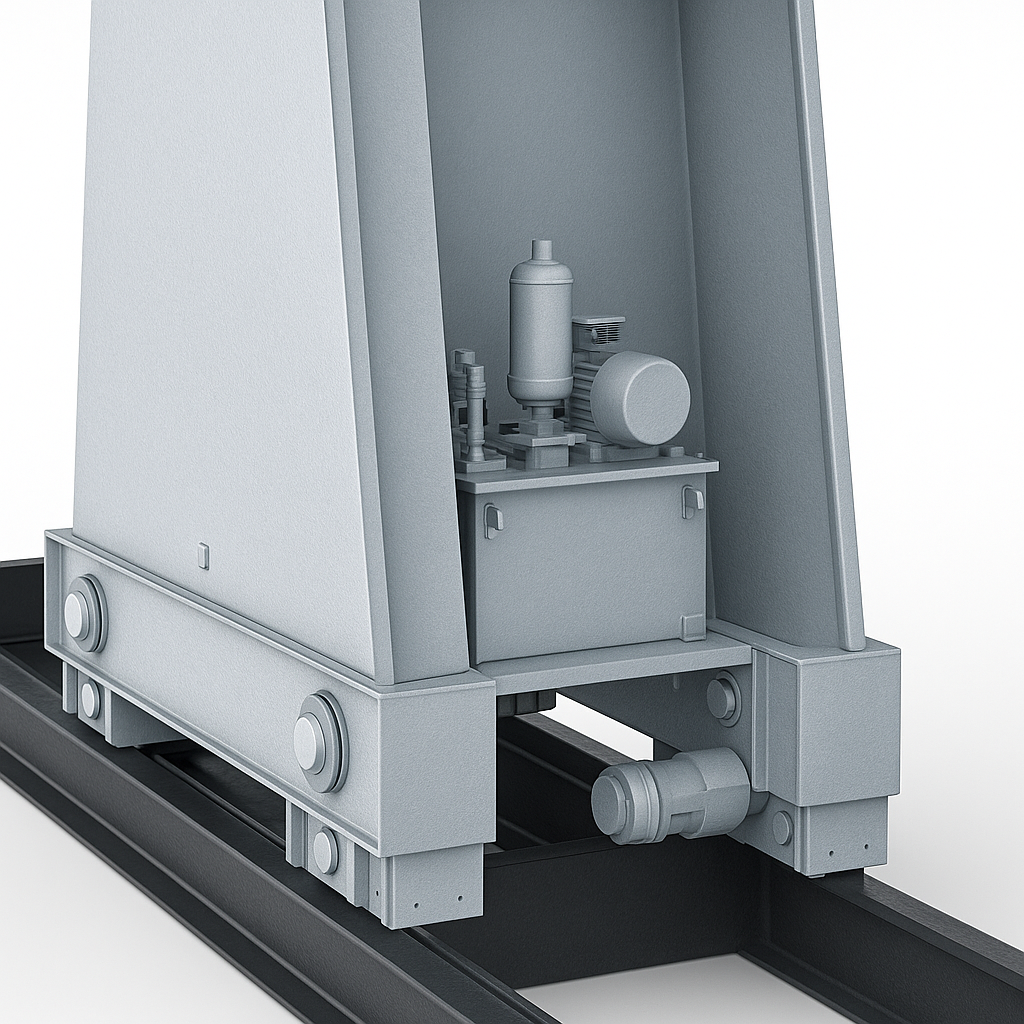

| ※ Each leg is a hydraulic product; |

| ※ Hydraulic pump station can be integrated into or on the base; |

| ※ Folding design meets the requirements of shipping containers; |

| ※ Effectively reduce load distribution; |

| ※ Mechanical locking capacity; |

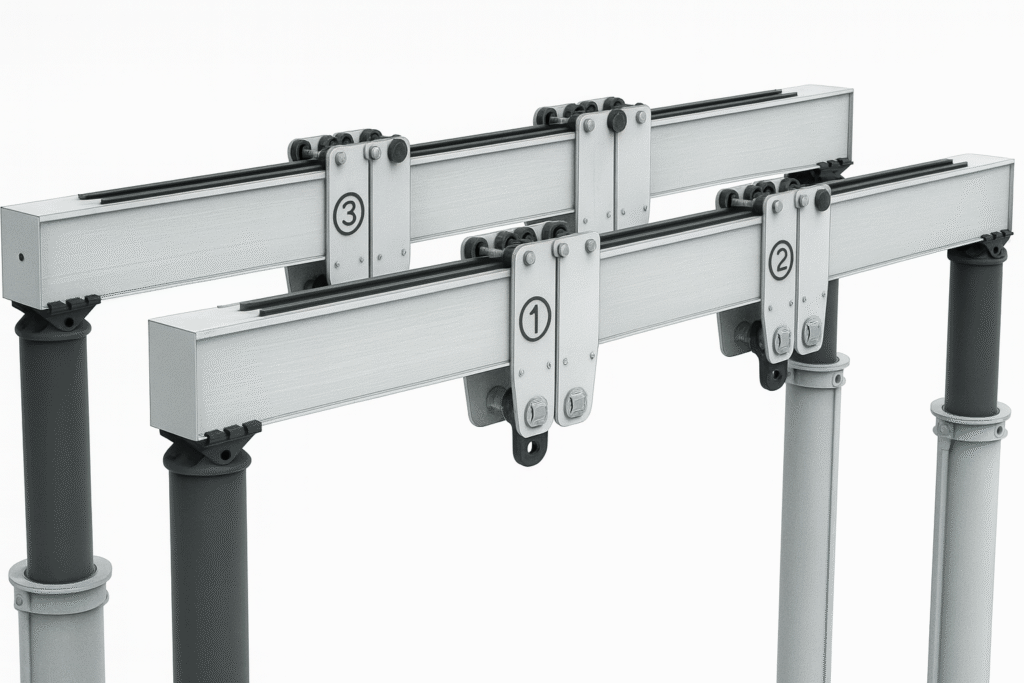

| ※ Available in 6m, 8m,10m and 12m lengths. Custom lengths available on request; |

| ※ Sold in pairs and includes lifting points and fork pockets for easy positioning on gantry towers; |

| ※ Each set consists of 4 units of side shift. |

| ※ Made of H-beam and steel plate welded together;

※ Designed in sections and are interchangeable; ※ Connected by bolts; |

| ※ Consists of remote control, special controller, encoder, detection switch and various electrical components.

※ A touch screen on the panel

|

Rated Crane Cases

Related blogs

Hydraulic gantry crane, mainly used for lifting and assembling large equipment (20t-1100t). The crane adopts a modular structural design, which facilitates the assembly, disassembly, and transfer work of the crane. The crane has a compact structure, which is suitable for both small space and outdoor use. Compared to conventional roll style bridge cranes, hydraulic gantry cranes operate more smoothly and have higher lifting and operating accuracy.

The hydraulic gantry crane adopts advanced hydraulic system and electrical control technology, which has the characteristics of fast start and precise computer control operation.The crane consists of 4 lifting modules, 2 main beam modules, and 4 trolley lifting point modules.

The main beam and the lifting module are connected through pressure plates and bolts to adapt to different span combinations at different positions;

The trolley is movable and suitable for lifting transformers of different sizes;

The electrical connections are all made using quick connectors, which can be directly plugged in at the installation site;

The hydraulic system has a simple structure, detachable components, convenient replacement and maintenance, greatly reducing maintenance costs.

After dismantling, the crane can be loaded into a 40 ft container;

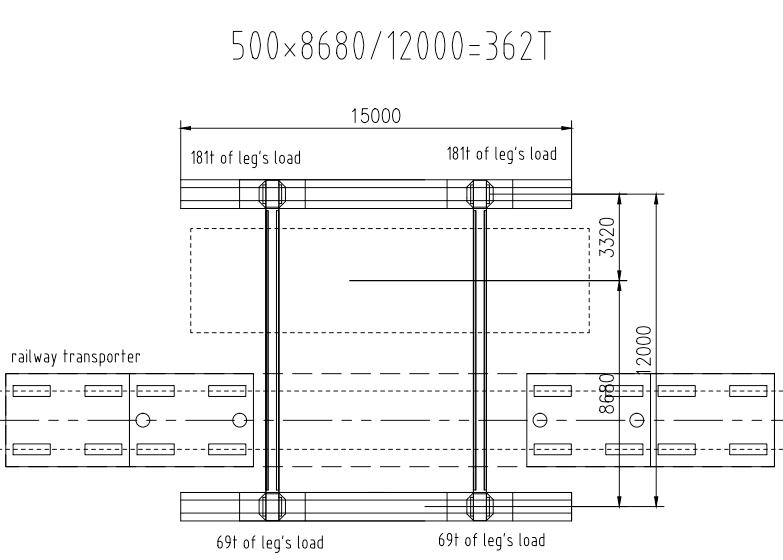

In order to ensure safety, the total bearing capacity of the crane is designed with a safety factor of 1.25 times the actual lifting weight(eg.500t). At the same time, considering that the movement of the lifting products along the main beam direction may cause serious unbalanced load, the lifting oil cylinder is designed with twice the weight of 500T (1 supporting leg is 250T, 4 for a total of 1000T). That is, the transformer is lifted to the side of the supporting leg, and the two supporting legs can jointly bear 500T (as shown in the following figure).

Each main beam can bear 250T at any position, and each main beam is equipped with 2 mobile trolleys, each of which can bear 125T.

The hydraulic system adopts reliable components and materials, which have good anti-interference performance. At the same time, the circuit control is stable and reliable, which can effectively ensure the normal operation of the crane. All oil cylinders are equipped with safety valves to prevent sudden descent during use. Even if the oil pipes fail, the crane can still maintain its original height position, avoiding safety accidents for personnel or equipment.

The operation of the crane adopts an industrial remote control, which is equipped with buttons and emergency stop switches for various working conditions. When external signal interference occurs, the crane can be stopped in a timely manner.

The crane is also equipped with multiple safety protection devices.

♣ Mechanical protection device: mechanical latch (optional);

♣ Hydraulic protection device: hydraulic quick break device, safety valve, brake system, brake system;

♣ Electric control protection device: overload sensing system, 95% rated load alarm, 105% rated load alarm and stop, normal (limit) stop for rise and fall, zero position protection, overcurrent (voltage) protection, undervoltage protection, short circuit protection, overheating protection, and leakage protection.

In order to ensure higher synchronization accuracy (running synchronization accuracy ≤ 50mm, lifting synchronization accuracy ≤ 5mm), the lifting and walking of the crane are equipped with encoders, which can provide real-time feedback on the operating position of the equipment. The control system adopts a dedicated PLC controller for construction machinery, which realizes functions such as crane walking, jacking, trolley lateral movement, safety protection, alarm, fault display, operation status and weight parameter display through the control program. To prevent longitudinal shaking of the transformer during movement, the control system has three speed selection gears to control the acceleration and deceleration of the operation based on the load condition.

Phone:(0086)18752670256

Email:motcrane@163.com

Address:NO.19, Liantai Road, Jingjiang, Jiangsu, China.