This client is an Egyptian enterprise specializing in steel structure design. The client intends to install 3ton single girder overhead cranes(4sets), 5ton single girder overhead cranes(6sets), and 10 ton double girder overhead cranes(1set) in six of its workshops.

Based on the client’s requirements, our scope of supply will be limited to providing electric hoist equipment for each crane.

In the procurement process of industrial lifting equipment, if only the core component, the electric hoist, is selected for purchase, multiple key factors need to be comprehensively considered to ensure its smooth installation and normal operation. Among them, the connection method between the electric hoist and the main beam, as well as the control voltage (the standard is usually 48V), are two important parameters that cannot be ignored.

The control voltage of an electric hoist is generally set at 48V to ensure operational safety and stability. As a standard voltage value in the industry, 48V can meet the needs of most application scenarios and effectively avoid safety hazards or equipment damage caused by excessively high voltage. Additionally, this voltage value is compatible with existing electrical control systems, simplifying the installation and commissioning process. Therefore, when purchasing an electric hoist, it is essential to confirm that its control voltage meets the requirements of the actual usage environment and that the related supporting equipment (such as controllers, cables, etc.) can support this voltage standard.

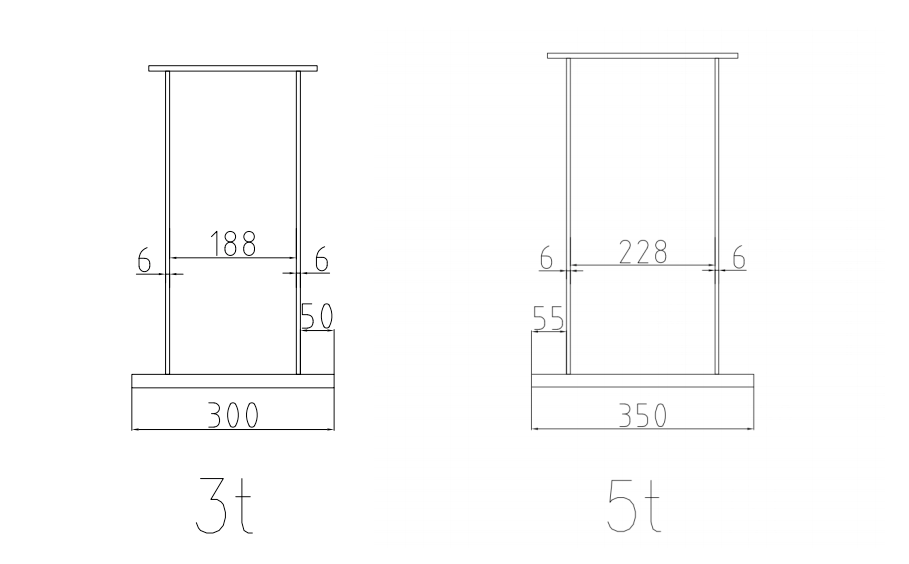

For single-girder electric hoists, their design features determine that they are directly suspended from a main girder. This structure is relatively simple, but it still requires precise measurement and confirmation of certain key parameters to ensure the accuracy and safety of the installation. Among them, the width of the lower flange plate of the main girder is one of the most important parameters. The width of the lower flange plate directly affects the fixed position of the electric hoist and its force distribution. For example, if the lower flange plate is too narrow, it may cause the electric hoist to be unable to be firmly fixed on the main girder; while if the lower flange plate is too wide, additional adapter devices may be needed to adjust the installation position. Therefore, before purchasing, technicians need to accurately measure and record this data to provide a basis for subsequent installation work.

In contrast, the installation of double-girder electric hoists is more complex. As this type of electric hoist needs to be placed between two main girders and move along the tracks, it is essential to accurately measure the distance between the two tracks on the main girders. This distance directly determines the gauge of the electric hoist, which is one of the crucial factors affecting the normal operation of the equipment. If the track spacing is too large or too small, the following problems may occur:

1) Installation difficulties: The electric hoist may not be correctly installed on the tracks.

2) Unstable operation: During operation, there may be issues such as stalling, deviation, or even derailment.

3) Increased risk of failure: Long-term operation may lead to mechanical wear or electrical faults, thereby reducing work efficiency.

Therefore, before purchasing a double-girder electric hoist, it is essential to measure and confirm in advance whether the track spacing meets the technical requirements of the selected equipment. Additionally, factors such as the material and flatness of the tracks should also be noted to ensure that the electric hoist can maintain efficient and stable operation throughout its service life.

Whether it is a single-girder or double-girder electric hoist, the installation process requires a comprehensive assessment based on the specific usage scenarios and environmental conditions. For instance, in some special circumstances (such as high-temperature, humid or corrosive environments), factors such as material compatibility and protective measures also need to be considered. Additionally, the rated load, lifting height, and operating speed of the electric hoist should be reasonably selected based on actual needs to ensure that the equipment can meet the requirements of production tasks.

In conclusion, a reasonable planning and a thorough understanding of the connection relationship between the electric hoist and the main beam as well as the control voltage standard are the fundamental guarantees for achieving efficient and safe lifting operations. Only by making adequate preparations during the procurement stage can a solid foundation be laid for subsequent installation and usage.

| Specifification | Electric hoist 1 | Electric hoist 2 | Electric hoist 3 |

| ♦ Load Capacity: | 3T | 5T | 10T |

| ♦ Lifting Height: | 10m | 10m | 10m |

| ♦ Working Class: | 2M/M5 | 2M/M5 | 2M/M5 |

| ♦ Lifting speed: | 5/0.8m/min | 5/0.8m/min | 0-5m/min |

| ♦ Hoist travelling speed: | 0-20 m/min | 0-20 m/min | 0-20 m/min |

| ♦ Control mode: | Remote control | Remote control | Remote control |

| ♦ Power Source: | 3P 380V 50HZ | 3P 380V 50HZ | 3P 380V 50HZ |

| ♦ Electric hoist color: | Red | Red | Red |

5Ton Electric Hoist Drawing(cick to download)

10Ton Electric Hoist Drawing(cick to download)