Semi gantry crane is an efficient material handling equipment that combines the advantages of overhead cranes and gantry cranes, especially suitable for factory workshops, warehouses and other working environments where space is limited or where it is not suitable to install full overhead cranes.

| ♦ Load Capacity: | 2t~30t |

| ♦ Crane Span: | 7.5m~35m |

| ♦ Lifting Height: | 6m、9m、12m… |

| ♦ Working Class: | A3~A6 |

| ♦ Control mode: | Wireless remote control / Cabin control |

| ♦ Protection class: | IP54/IP55 |

| ♦ Power Source: | 3P 380V 50HZ or others |

| ♦ Working temperature: | -20℃ to 45℃ |

| Standard Beam(Box-type) |

| Standard Electric Hoist |

| NO VFD Control |

| Working Class: A3 |

| ISO Standard |

| European Beam(Low Headroom) |

| European Electric Hoist(Maintenance Free) |

| VFD Control |

| Working Class:A4/A5 |

| ISO/FEM Standard |

| Standard Beam(Box-type) |

| Winch trolley |

| VFD Control |

| Working Class:A3~A6 |

| ISO Standard |

| ※ SWL(t):0.8t-32ton |

| ※ HOL(m)Max.:90m |

| ※ Stepless control trolley(VDF control); |

| ※ Rotation mounting design for lifting motor; |

| ※ Smart driving,higher efficiency; |

| ※ Heavy duty motor, 60%ED rating; |

| ※ Heavy duty galvanized wire rope; |

| ※ Standard features include safety monitoring; |

| ※ SWL(t):0.8t-20ton |

| ※ HOL(m)Max.:30m |

| ※ Shell is welded by robot to ensure the strength; |

| ※ Heavy duty galvanized wire rope; |

| ※ Meet the requirements of M3/M4 work level; |

| ※ Motor load duration increases to 30%; |

| ※ Imported brand contactors and improved limit methods; |

| ※ Energy efficiency rating is not lower than level 2; |

| Common types: |

| ♦ Conical asynchronous motor

♦ Soft start motor

♦ 3-in-1 motor (Can replace European brands) |

| Common types: |

| ♦ “3-in-1” motor

Motor, reducer & brake are combined into 1 drive device with the advantages of easy installation, high transmission efficiency and low noise. |

Rated Crane Cases

Related blogs

The structure of semi gantry cranes is characterised by the fact that one side of the end girder runs along the overhead crane track and the other side of the outrigger travels along the ground track, thus forming a unique layout of ‘semi overhead, semi gantry’.

This design not only saves space, but also works with the existing overhead crane system to significantly improve operational efficiency. With the outrigger structure on one side and the end girder of the overhead travelling crane on the other, it fully combines with the structural characteristics of the plant to realise the efficient use of space.

As an economical and practical crane solution, the semi gantry crane has the following advantages:

1. compared with overhead cranes, it reduces the occupation of workshop space by columns;

2. compared with the gantry crane, reducing the demand for space in the production area.

MHB semi gantry cranes can be used with CD-type or MD-type electric hoists, the trolley of electric hoist runs along the I-beam flange on the lower flange of the main beam. After decades of technical development and continuous improvement, the equipment has been standardised for production processes and its working class is usually A3.

♦ Standard Capacity:1t/2t/3t/5t/10t/16t/20t

♦ Crane Span(c/c):7.5m~35m

♦ Lifting height:6m/9m/12m/18m/24m/30m

♦ Working class:A3

♦ Crane control mode:Floor control & Remote control

♦ Lifting speed:8m/min

♦ Hoist(Trolley) Traveling speed:20m/min

♦ Crane Traveling speed:20m/min、30m/min

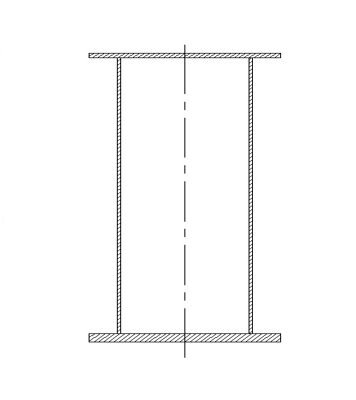

♦ Main beam Sectional view

MHB-X semi gantry cranes can be used in conjunction with European-style electric hoists, whose trolley runs along the flange plate under the main beam. After decades of technological development and continuous improvement, the equipment has achieved a standardised production process and its working class is usually A5.

♦ Standard Capacity:1t/2t/3t/5t/10t/16t/20t

♦ Crane Span(c/c):7.5m~35m

♦ Lifting height:6m/9m/12m/18m/24m/30m

♦ Working class:A4/A5

♦ Crane control mode:Floor control & Remote control

♦ Lifting speed:Dual-speed or frequency conversion

♦ Hoist(Trolley) Traveling speed:frequency conversion

♦ Crane Traveling speed:frequency conversion

♦ Main beam Sectional view:square box-type structure

MGB semi gantry cranes can be used with double girder electric hoists and double girder winch trolleys, with the hoisting trolley running on rails on the two main girders. After decades of technological development and continuous improvement, the equipment has been standardised for production processes and its working class is usually A3-A6.

♦ Standard Capacity:5t~30t

♦ Crane Span(c/c):7.5m~35m

♦ Lifting height:6m/9m/12m/18m/24m/30m

♦ Working class:A3~A6

♦ Crane control mode:Floor control & Remote control

♦ Lifting speed:Single speed or frequency conversion

♦ Hoist(Trolley) Traveling speed:Single speed or frequency conversion

♦ Crane Traveling speed:Single speed or frequency conversion

Phone:(0086)18752670256

Email:motcrane@163.com

Address:NO.19, Liantai Road, Jingjiang, Jiangsu, China.