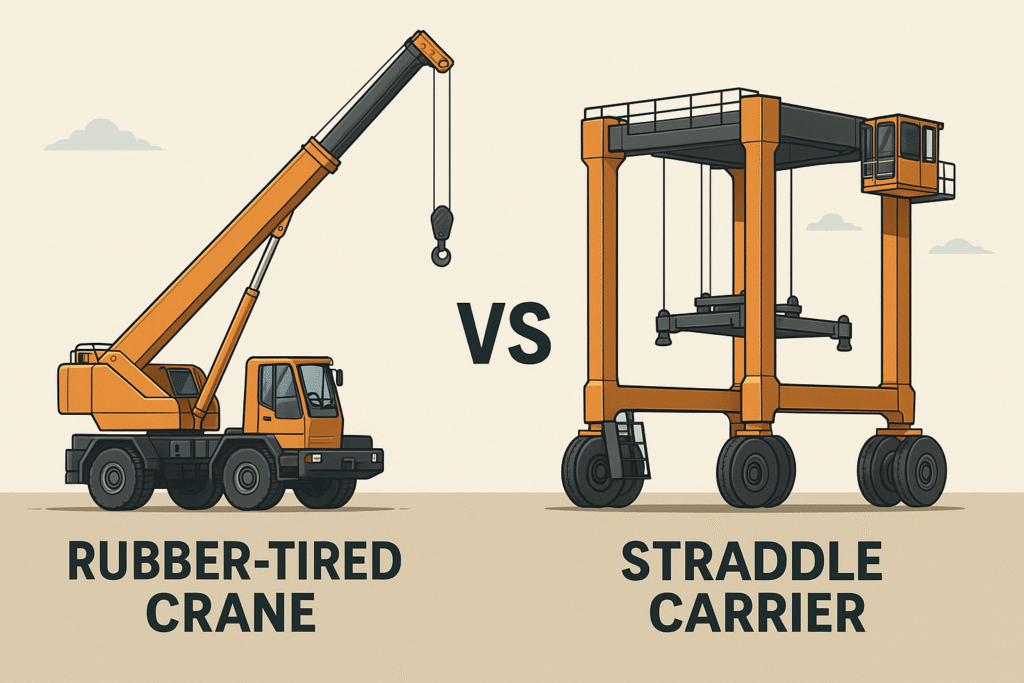

Rubber-Tired Crane vs Straddle Carrier:

Which is the Right Choice for Your Lifting Needs?

Introduction

When it comes to heavy lifting and container handling in ports, logistics yards, steel plants, and large-scale construction projects, Rubber-Tired Cranes (RTCs) and Straddle Carriers are two of the most popular solutions.

Although both can lift and transport heavy loads, they differ significantly in design, operation, efficiency, and application suitability.

Choosing the right equipment can directly impact your operational efficiency and costs.

What is a Rubber-Tired Crane?

A Rubber-Tired Crane is a mobile lifting machine mounted on a multi-axle chassis with large rubber tires, allowing it to operate without fixed tracks.

Key features include:

♣ Telescopic or lattice boom for extended reach and high lifting capacity.

♣ 360° rotating superstructure for flexible lifting from multiple angles.

♣ Diesel, hybrid, or electric power options depending on site requirements.

♣ Excellent off-road performance, making it ideal for uneven or rough terrains.

Typical Specifications:

♣ Lifting capacity: 10ton–300ton

♣ Max lifting height: up to 80m

♣ Applications: bridge construction, steel structure erection, wind turbine installation, heavy machinery relocation.

What is a Straddle Carrier?

A Straddle Carrier is a large, self-propelled, U-shaped or portal-frame vehicle designed to lift cargo from above and transport it within the yard.

Key features include:

♣ Top-lift spreader or lifting slings to pick up containers or oversized cargo.

♣ Self-loading and self-transporting capability without external trailers.

♣ Small turning radius or even on-the-spot pivoting, ideal for crowded yards.

♣ Designed for container stacking up to 3–4 high, improving yard space utilization.

Typical Specifications:

♣ Lifting capacity: 35ton–150ton (custom models available)

♣ Lifting height: 6–12m

♣ Applications: port container yards, steel plants, shipyards, oversized beam and truss transport.

Side-by-Side Comparison Table

| Feature | Rubber-Tired Crane | Straddle Carrier |

|---|---|---|

| Mobility | ♠ Excellent off-road capability | ♠ Best on flat, paved surfaces |

| Lifting Height | ♠ Up to 80m | ♠ Usually up to 12m |

| Transport Ability | ♠ Requires separate truck/trailer | ♠ Self-transporting |

| Turning Radius | ♠ Larger, needs space | ♠ Small radius or pivot turn |

| Primary Use | ♠ Construction, heavy lifting at height | ♠ Container & oversized cargo yard transport |

| Setup Time | ♠ Requires stabilizer deployment | ♠ Minimal |

| Space Efficiency | ♠ Needs wide working area | ♠ High stacking density |

Applications in Real-World Scenarios

1. Port & Container Yard

♣ Straddle Carrier Advantage: Can pick up containers directly from the quay crane and stack them in the yard without extra transport equipment.

♣ Rubber-Tired Crane Role: Assists in lifting heavy machinery or oversized cargo at the port.

2. Steel Structure Manufacturing

♣ Straddle Carrier: Efficiently transports long trusses or beams from workshop to storage yard.

♣ Rubber-Tired Crane: Lifts and positions heavy steel components during assembly.

3. Construction Projects

♣ Rubber-Tired Crane: Perfect for high-rise, bridge, and wind turbine installations due to long boom reach.

♣ Straddle Carrier: Useful for moving large pre-fabricated sections around the site.

Cost & Maintenance Considerations

♣ Initial Investment: Straddle carriers tend to be more expensive due to their specialized design and high automation potential.

♣ Operating Costs: RTCs have simpler structures and lower specialized maintenance needs, while straddle carriers may require professional technicians for hydraulic and control systems.

♣ Labor Requirements: Straddle carriers can often be operated by a single person; cranes usually need a dedicated operator plus ground signalers for safety.

Choosing the Right Equipment

The decision between a Rubber-Tired Crane and a Straddle Carrier depends on:

♣ Load Type & Dimensions

♣ Lifting Height Requirements

♣ Yard or Site Conditions

♣ Frequency of Operations

♣ Budget and ROI Goals

If your operation involves frequent container or long cargo movement in a fixed yard, a Straddle Carrier offers unmatched efficiency.

If you need versatile heavy lifting across multiple or uneven sites, a Rubber-Tired Crane is the better choice.

Conclusion

Both Rubber-Tired Cranes and Straddle Carriers play critical roles in modern material handling and logistics. By understanding their unique advantages and limitations, you can select the right machine to maximize productivity, minimize costs, and improve overall operational flow.

For expert advice or to explore customized lifting solutions, contact us today — we can help you design the perfect setup for your project.