How to Select a 30-Ton Hydraulic Gantry Crane for Industrial Projects

In heavy industry, 30-ton hydraulic gantry cranes are commonly used for lifting and transferring large finished or semi-finished equipment (such as pressure vessels and transformers) within workshops. They are particularly suitable for workshops without overhead cranes, or for small or complex workspaces limited by site height clearance, span, and ground load-bearing capacity, or where conventional lifting equipment cannot be deployed.

Compared to standard industrial lifting equipment (including electric overhead cranes and electric gantry cranes), hydraulic gantry cranes offer significant advantages in overall operational stability, four-point or two-point lifting synchronization accuracy, and rated safety load factor. Therefore, accurate evaluation of key parameters—especially the highest point working load and effective lifting stroke—during the selection phase directly impacts the equipment’s operational reliability and safety.It also determines whether the crane is suitable for the engineering project throughout its entire lifecycle.

Based on our company’s experience exporting 30-ton hydraulic gantry cranes to the Russian market, this article systematically elucidates the correct selection principles and key technical considerations for this type of equipment in heavy industrial scenarios, focusing on actual engineering application needs. For industrial users planning hydraulic gantry crane projects or requiring customized heavy-duty lifting solutions, the selection phase is crucial.

I. Which industrial projects are typically suitable for a 30-ton hydraulic gantry crane?

In practical applications, 30-ton hydraulic gantry cranes are commonly used in the following industrial scenarios:

♣ Lifting heavy finished or semi-finished products in industrial workshops;

♣ Transferring workpieces with complex geometric shapes (including regular and irregular shapes), such as pressure vessels, gas cylinders, and storage tanks;

♣ Precision assembly tasks requiring high stability in the lifting process, four-point synchronization, and synchronous positioning accuracy;

Compared to traditional electric gantry cranes, hydraulic gantry cranes exhibit superior operational stability, smoother lifting characteristics, and higher precision dual-gantry synchronous control capabilities under low-speed, heavy-load conditions. Therefore, they are particularly suitable for industrial scenarios with large loads, relatively low operating frequency, but stringent requirements for process reliability and control precision.

II. Three Core Technical Parameters for Selecting a 30-Ton Hydraulic Gantry Crane in Industrial Engineering Projects

When selecting a 30-ton hydraulic gantry crane for industrial projects, relying solely on the nominal “lifting capacity” is insufficient.The following three technical parameters are core elements that customers must evaluate during the selection process:

1. Rated Lifting Capacity and Safety Margin

The rated lifting capacity (30 tons) refers to the maximum static load that the equipment is allowed to lift under standard operating conditions. During lifting, the net weight of the lifted product, the weight of the lifting equipment (moving trolley), the dynamic load coefficient during starting and braking, wind load, and the cumulative effects of eccentric loads must be comprehensively considered to set a reasonable design safety margin.

Our company’s order for a 30-ton hydraulic gantry crane in Russia was designed for a 1.5 times rated load condition. Before leaving the factory, it underwent a combined static and dynamic load test at 150% of the rated load to verify its redundant load-bearing capacity.

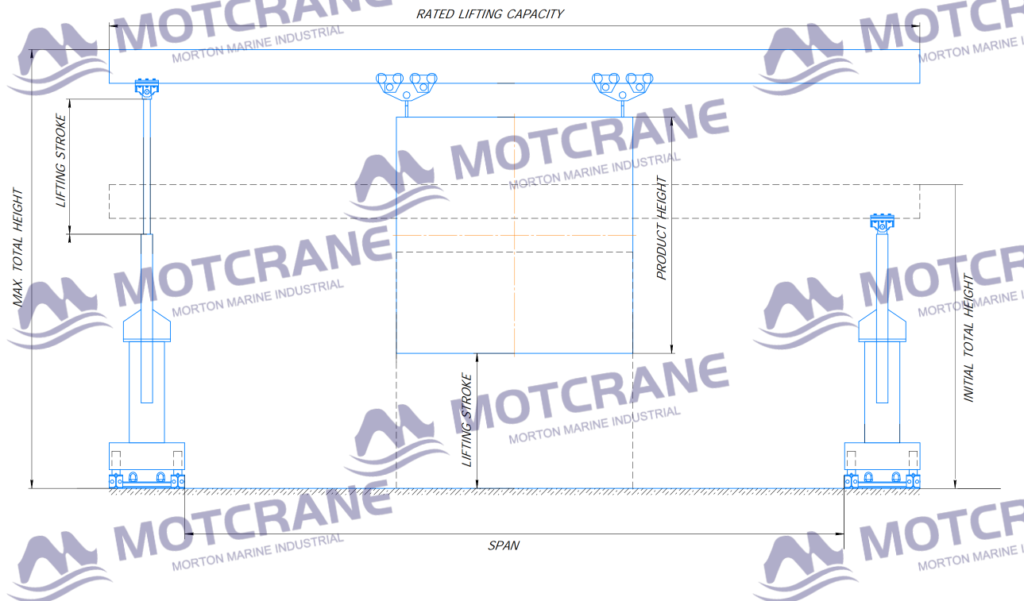

2. Lifting Height and Main Beam Span

The lifting height (working space below the hook) and the main beam span together determine the overall configuration of the equipment, the outrigger arrangement, and the main structural stiffness distribution scheme. The lifting height is the most crucial because the height of the object being lifted is not always uniform. Therefore, customers need to determine the minimum and maximum heights below the hook of the hydraulic gantry crane, i.e., the lifting stroke.This lifting stroke is a critical parameter in any heavy-duty hydraulic gantry crane project, directly affecting structural height, cylinder selection, and cost.

In actual industrial projects, the lifting height is often the primary factor influencing the structural design and cost configuration of a hydraulic gantry crane.Standardized equipment often fails to fully accommodate site-specific constraints, lifting stroke variations, and synchronization accuracy requirements in real industrial environments.

3. Multi-Point Synchronous Lifting Accuracy

In heavy-duty industrial projects, the synchronous lifting accuracy of a 30-ton hydraulic gantry crane is often a crucial indicator of the overall hydraulic system design level. Hydraulic gantry cranes commonly use a dual/four-cylinder parallel drive mode to achieve synchronous lifting. If the synchronization error exceeds the allowable threshold (usually ≤±10mm), it will cause structural risks such as main beam torsion, outrigger reaction force imbalance, and excessive local stress. For 30-ton class equipment, synchronous control accuracy not only affects operational stability but is also a key quality indicator reflecting the response characteristics of the hydraulic servo system, sensor measurement accuracy, and controller algorithm.In practice, this parameter often distinguishes a standard supplier from a true custom hydraulic gantry crane manufacturer.

The following schematic illustrates the key dimensional and functional parameters of a typical 30-ton hydraulic gantry crane used in industrial projects.

III. Why do 30-ton hydraulic gantry cranes often require custom design?

Unlike standard catalog equipment, most 30-ton hydraulic gantry cranes are engineered as custom hydraulic gantry crane solutions based on site-specific constraints.In actual engineering projects, 30-ton hydraulic gantry cranes are almost always custom-designed projects, rather than standard equipment purchases (due to different height and span requirements). The main reasons include:

♣ Significant differences in workshop and space conditions

♣ Different load sizes and center of gravity distributions

♣ Different lifting height requirements

Only through targeted structural optimization can a customized solution better suited to the customer’s needs be formed.

IV. Case Study: Selection Approach for a 30-ton Hydraulic Gantry Crane in Russia

In this 30-ton hydraulic gantry crane project, the customer’s core concerns focused on the following aspects:

♣ Stability during the lifting process

♣ Reliability of multi-point synchronous control

♣ Safety performance under full load and overload conditions

To address these requirements, we optimized the entire process from design and manufacturing to factory acceptance, focusing on industrial heavy-duty application scenarios.

The equipment ultimately completed load tests of 30–45 tons at the factory, operating smoothly under full load with synchronization accuracy meeting customer expectations, laying the foundation for its long-term use in Russian industrial sites.

V. How to Choose a Reliable Hydraulic Gantry Crane Manufacturer?

For industrial projects, when selecting a hydraulic gantry crane manufacturer, it is recommended to focus on the following capabilities:

♣ Custom design and engineering assessment capabilities

♣ Ability to provide complete technical solutions rather than a single quote

♣ Actual delivery experience with similar heavy-duty projects

Only manufacturers with complete project delivery experience are more likely to understand the true needs of industrial customers in terms of safety, stability, and long-term use.

For industrial users planning hydraulic gantry crane projects or requiring customized heavy-duty lifting equipment of 30 tons or more, technical judgment during the selection phase is particularly crucial.

If you have specific operating parameters (lifting capacity, lifting height, lifting stroke, span, or synchronization accuracy requirements), it is recommended to conduct technical communication with an experienced hydraulic gantry crane manufacturer, such as MOTCRANE, at the early stage of the project to avoid rework or safety hazards later.