How a 30-Ton Hydraulic Gantry Crane Achieves High-Precision Synchronous Lifting

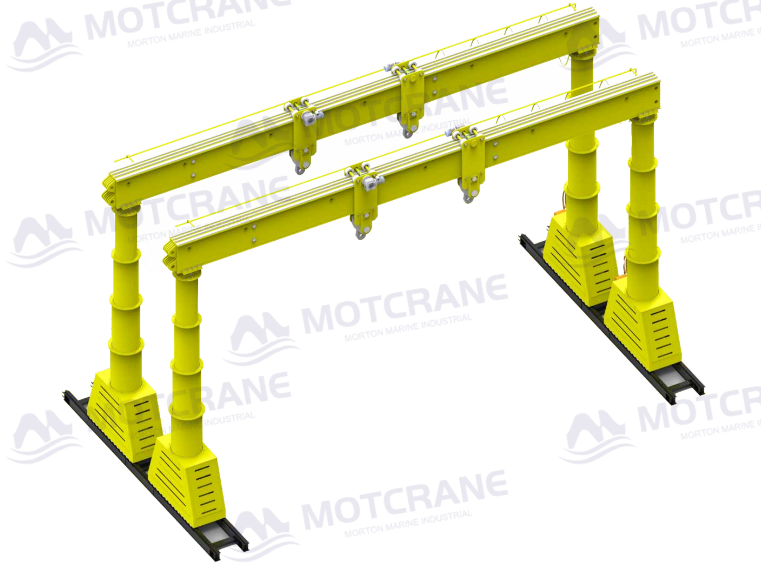

In heavy industrial lifting scenarios, a 30-ton hydraulic gantry crane is typically deployed to lift large and extra-long rigid structures such as pressure vessels, storage tanks, and transformers. Compared with electric lifting equipment, these applications impose significantly higher requirements on synchronization accuracy and operational stability.

Although the working duty class is generally M3, the technical challenge lies not in frequency of operation, but in achieving safe and controlled lifting under heavy loads. For this reason, synchronization control becomes a defining feature of a heavy duty hydraulic gantry crane system. In most heavy industrial applications, such systems are engineered as custom hydraulic gantry crane solutions rather than standard catalog models.

In practical engineering, many lifting failures are not caused by insufficient rated capacity, but by asynchronous two-point or four-point lifting. Uneven cylinder motion can generate structural torsion, eccentric loading, and excessive outrigger stress, ultimately damaging both equipment and cargo.

Therefore, achieving high-precision synchronous lifting is one of the core technical issues in any hydraulic gantry crane project.

I. Why Must Synchronous Lifting Accuracy Be a Priority for 30-Ton Hydraulic Gantry Cranes?

Unlike single-point lifting equipment (such as electric gantry cranes), 30-ton hydraulic gantry cranes typically employ a two-point or four-point synchronous lifting structure.

In this structural system:

* Displacement error at any outrigger

* Speed difference in any hydraulic cylinder

* Pressure fluctuation in any hydraulic circuit

can be amplified into eccentric loading or torsion deformation of the overall structure.

Under heavy-load and low-speed operating conditions, if synchronization error exceeds the allowable range, the following risks may occur:

* Additional torsional moment in the main beam

* Uneven reaction forces at the outriggers, leading to localized overload of the foundation

* Tilting or structural deformation of the lifted workpiece

Therefore, in a 30-ton hydraulic gantry crane, synchronous lifting is not an “optional function”, but a critical performance parameter that defines the safety boundary of the equipment.

II. Basic Principles of Synchronous Lifting in Hydraulic Gantry Cranes

In engineering practice, 30-ton hydraulic gantry cranes typically adopt the following synchronization control approach:

1. Parallel Lifting Structure with Multiple Cylinders

A common configuration consists of dual or four hydraulic cylinders arranged in parallel, powered by a centralized hydraulic power unit to initiate simultaneous lifting.

However, it must be emphasized:

Parallel operation ≠ inherent synchronization

Hydraulic parallel connection alone cannot guarantee identical displacement at each lifting point.

2. Displacement Detection and Feedback System

To achieve high-precision synchronization, displacement monitoring devices must be integrated. Typical solutions include:

* Stroke sensors

* Linear displacement encoders

* Built-in cylinder position sensors

By continuously monitoring real-time displacement at each lifting point, the system establishes a data foundation for precise closed-loop control.

3. Synchronization Control Logic and Compensation Mechanism

Within the control system, displacement data from each lifting point is continuously compared:

* If one cylinder lags, the system automatically increases flow to compensate.

* If one cylinder advances, the system restricts its lifting speed.

This closed-loop feedback mechanism is the fundamental principle behind achieving millimeter-level synchronization accuracy.

III. What Factors Most Commonly Compromise Synchronous Lifting Accuracy?

Even when the design is theoretically sound, synchronization accuracy may still be affected by:

* Center-of-gravity deviation of the lifted object

* Unequal loading conditions on individual outriggers

* Variations in ground bearing capacity

* Differences in internal friction of the cylinders

* Changes in hydraulic oil temperature affecting viscosity

For this reason, 30-ton hydraulic gantry cranes are almost always engineered as customized systems rather than standardized products.

IV. Synchronization Control Practice in the Russian 30-Ton Hydraulic Gantry Crane Project

In our delivered Russian 30-ton hydraulic gantry crane project, the client’s core requirements for synchronous lifting included:

* Stable synchronization throughout the entire lifting stroke

* Prevention of structural torsion under low-speed heavy-load conditions

* Maintenance of synchronization accuracy during both rated and overload testing

Before delivery, the crane underwent load testing from 30 to 45 tons (150% of rated capacity), focusing on:

* Stability of multi-point synchronous lifting

* Synchronization performance during combined lifting and traveling operations

* Structural response under extreme load conditions

The test results confirmed that synchronization accuracy remained within the safe range for heavy industrial applications throughout the full lifting stroke.

V. Synchronous Lifting Capability as an Indicator of Engineering Level

For 30-ton hydraulic gantry cranes, synchronization capability is not determined by a single component. It is the result of a comprehensive engineering system that includes:

* Hydraulic system architecture

* Control algorithm and feedback precision

* Structural stiffness and load path optimization

* Practical project validation and field experience

This is why, in heavy industrial projects, selecting a hydraulic gantry crane manufacturer with proven heavy-duty project delivery experience is often more critical than comparing nominal lifting capacity alone.