Custom Hydraulic Cylinders – The Power Core of High-Performance Cranes

In the modern lifting industry, the stability, safety, and operational efficiency of equipment directly influence enterprise operating costs and project timelines. Among the components of hydraulic cranes, Custom Hydraulic Cylinders are one of the key actuating elements that determine hydraulic lifting performance. Whether for lifting heavy loads, repositioning equipment, or extending and folding boom structures, high-performance hydraulic cylinders directly affect the positional accuracy, operating speed, and system reliability of cranes. Therefore, selecting a custom hydraulic system tailored to the equipment’s operating conditions is a critical step in enhancing overall machine performance and market competitiveness.

What Is a Hydraulic Cylinder and Why Are Cranes Dependent on It?

A hydraulic cylinder is an actuating device that transforms hydraulic energy into linear mechanical motion. It is primarily composed of a cylinder barrel, piston, piston rod, sealing system, and end covers. Compared to traditional mechanical transmission methods, hydraulic cylinders offer several key advantages:

- High output force, making them suitable for heavy-duty applications;

- Stable operation with precise control; compact design, enabling integration into complex mechanical configurations;

- The ability to be extensively customized according to specific project requirements.

In crane manufacturing, hydraulic cylinders are not only employed in lifting operations but also widely utilized in steering control, boom extension and retraction, outrigger deployment, and structural folding. These functions underscore their role as a core component in ensuring the efficient and safe performance of high-end cranes.

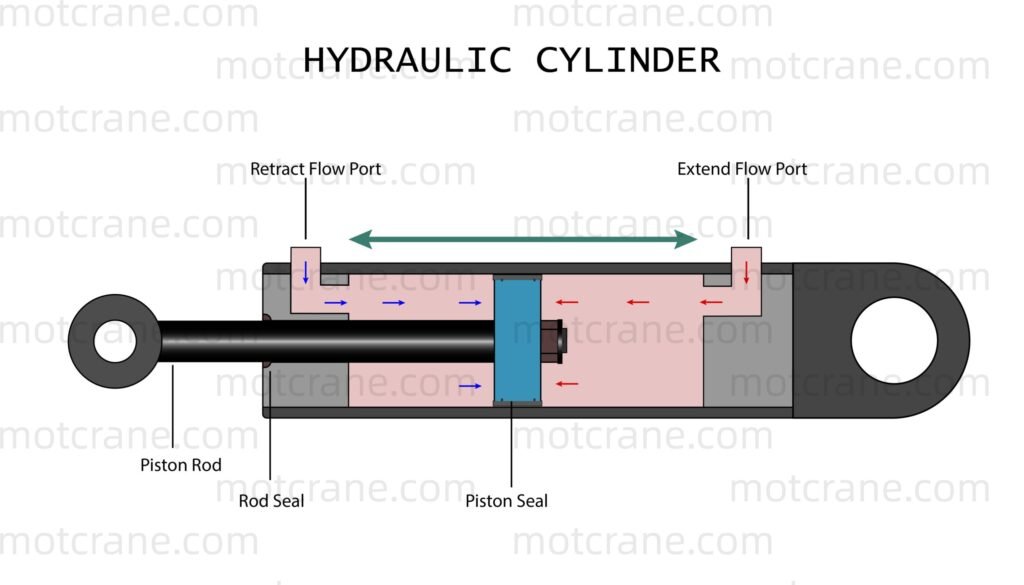

The working principle of hydraulic cylinders

The working principle of a hydraulic cylinder is highly stable and reliable:

The hydraulic pump converts mechanical energy into high-pressure oil, driving the piston to move in a straight line within the cylinder barrel, thereby enabling the piston rod to output a powerful thrust or pull force. By regulating the flow and direction of the hydraulic oil through the control valve, precise control of the movement process, running speed and direction of the actuator can be achieved.

This system can precisely lift heavy objects, smoothly advance structures, sensitively adjust steering, and synchronously move multiple components. This is precisely the fundamental reason why modern heavy lifting equipment widely relies on hydraulic transmission technology.

Common Types of Custom Hydraulic Cylinders

To adapt to the structural features and operating conditions of different lifting equipment, hydraulic cylinders can be designed in various types according to requirements:

- Single-acting hydraulic cylinder: It is suitable for simple lifting and supporting operations. The return stroke relies on gravity or spring return. The structure is simple and maintenance is convenient.

- Double-acting hydraulic cylinder: It is suitable for lifting equipment that requires precise control of bidirectional movement. It can provide active driving force in both directions and has higher stability, safety and controllability.

- Telescopic hydraulic Cylinder: It adopts a multi-stage sleeve structure design, achieving a longer stroke in a compact installation space, and is widely used in equipment such as telescopic boom cranes and hydraulic gantry cranes.

- Steering special hydraulic cylinder: Specifically designed for steering control systems, it is commonly found in large mobile lifting machinery and can achieve precise direction adjustment and dynamic response.

Through customized design, hydraulic cylinders can fully match the structural layout, load-bearing capacity and working frequency of cranes, ensuring the efficient and reliable operation of the system.

Key Applications of Hydraulic Cylinders in Cranes

The hydraulic cylinder is not merely used as a “lifting tool”, but as the core power execution unit of the entire lifting equipment. It is widely applied in various heavy mechanical equipment, and its specific applications are as follows:

Hydraulic cylinders are mainly used for:Lifting control of the mast,Load balancing regulation,Stability adjustment of structural posture.

Hydraulic cylinders are applied to:Height adjustment of the entire vehicle,Control of the grasping height of container lifting gear,Dynamic stability system during steering and driving.

The key functions that hydraulic cylinders undertake include:Synchronous extension and retraction movement of multi-section booms,Precise adjustment of the lifting Angle of the boom,High-precision positioning in hoisting operations.

4. Foldable Knuckle Boom Crane

The hydraulic cylinder performs the following core operations:The folding and unfolding movements of the articulated arm,Precise operations in space-constrained environments,Smooth lifting and positioning under heavy load conditions.

In conclusion, hydraulic cylinders play a multi-dimensional and high-precision role in power drive in modern lifting equipment and are key components that ensure the safe and efficient operation of the equipment.

Why Custom Hydraulic Cylinders Are the Best Choice for Crane Buyers

Compared with standardized cylinders, custom hydraulic cylinders demonstrate significant advantages in multiple aspects:

– It can be fully adapted to the structural dimensions of the equipment.

– Customize the cylinder diameter and pressure rating according to the actual load requirements;

– Select appropriate sealing materials based on the specific working environment.

– Support the configuration of a buffer system to effectively extend the service life of the equipment.

– It also helps to improve the efficiency of lifting operations and reduce the occurrence rate of faults.

– For customers purchasing lifting equipment or planning new projects, choosing cranes equipped with high-quality custom hydraulic cylinders not only helps reduce later maintenance costs but also achieves a higher return on investment.

Why Choose MOT Crane?

At MOTcrane, we not only offer lifting equipment, but are also committed to providing customers with overall hydraulic solutions based on application scenarios.

Whether you need customization

We can all configure the most suitable hydraulic system according to your project requirements. At the same time, we also offer standard cranes, including overhead cranes, gantry cranes, jib cranes and many other options.

Get a Custom Crane Solution Now

If you are looking for a reliable crane manufacturer, contact us today to: sales@motcrane.com

Design a customized crane for your project

Visit our product pages or send your inquiry now and let our engineers help you choose the right crane system.