♠ Customer: Large industrial printer & packaging plant

♠ Application: Low-headroom installation of a long, heavy machine module on a concrete plinth

♠ Load type: Rigid machine section with sensitive components (requires fine alignment)

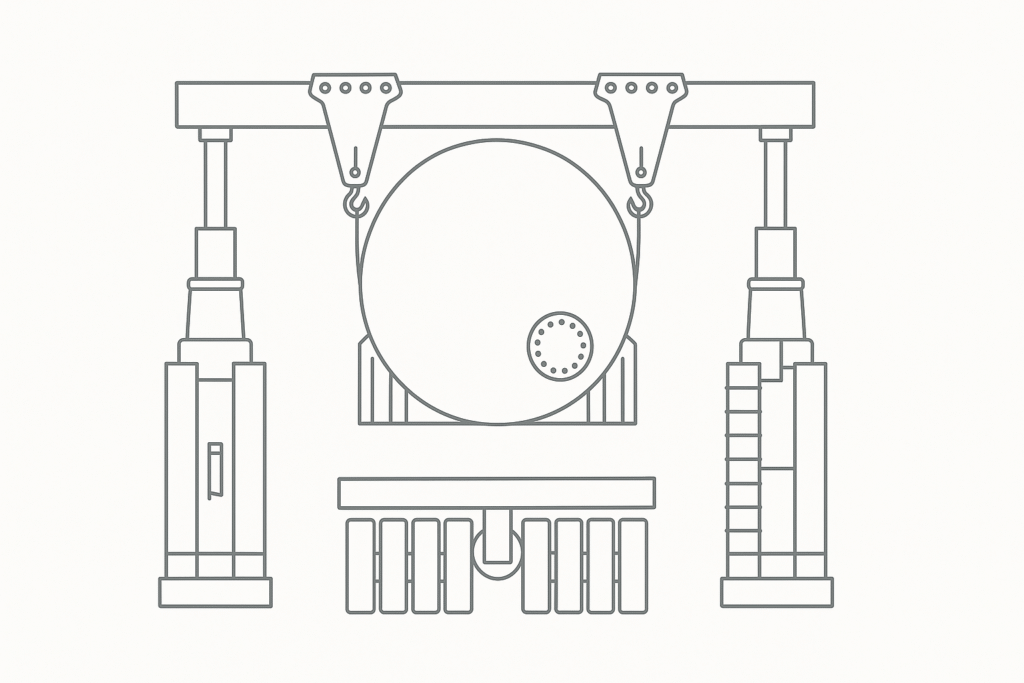

♠ Equipment supplied: 40-ton hydraulic gantry (two-post), header beam, powered pump unit, steel track, rigging set, remote control

♠ Outcome: Safe, synchronized lift-and-set with millimeter-level alignment and minimal line downtime

Installing a bulky machine inside an existing hall meant:

♣ Low roof height / limited headroom—mobile crane access was impossible.

♣ Tight aisles & finished floors—no heavy crane outriggers allowed; point loads had to be controlled.

♣ Precision alignment—the machine needed to land on anchor bolts along a concrete plinth and match line height.

Compared with an overhead crane or mobile crane, a hydraulic gantry:

♣ Works comfortably under low ceilings; telescopic cylinders create lift without boom clearance issues.

♣ Rolls on track to traverse the load in small increments—ideal for “lift, move a little, set” workflows.

♣ Offers synchronized control (±1–3 mm typical) for accurate positioning on foundations.

♣ Brings lower site disruption—compact footprint, no exterior crane logistics.

♣ Track layout & load study

Temporary steel rails fixed along the plinth; floor bearing checks done to keep concrete within allowable pressure.

♣ Header beam & rigging

Spreaders and soft slings protected machine skins; lift points balanced for center-of-gravity control.

♣ Synchronized lift

Gantry raised the load just above final height; remote pendant maintained cylinder synchronization.

♣ Slow traverse & set

Inch-by-inch travel along rails; final set on grout pads with dial indicator checks.

♣ Commissioning

Oil-free wipe-down, torque checks, documentation and operator briefing.

♣ Result

Installation finished within a planned shift, alignment achieved to tolerance, and the production line could proceed with wiring and commissioning the same day.

♣ No roof modifications or temporary beam installs

♣ Short shutdowns and predictable schedules

♣ High positioning accuracy for anchor-bolt or plinth sets

♣ Lower total project cost versus bringing in big mobile cranes indoors

♣ Can a 40-ton hydraulic gantry crane work if my ceiling is only 4–5 meters?

Yes. With a collapsed height around 2.5–3.2 m and a modular header beam, a 30-ton gantry is designed for low-headroom lifts inside factories.

♣ What floor information do you need?

Concrete thickness, grade, and reinforcement. We calculate line loads of the gantry bases/rails and recommend pad size or shoring if needed.

♣ How is synchronization achieved?

The power pack and valve manifold balance cylinder flow; operators use a remote pendant to keep posts level during lift, traverse, and set.

♣ What documents will I receive?

Load study summary, rigging plan, track layout, method statement, inspection checklist and commissioning records (on request).

♣ Can you supply rental + operators?

Depending on region, we can supply equipment, supervision, or turnkey service via our partner network. Ask our team for availability.

| Specifification | HYDRAULIC GANTRY CRANE 40T |

| ♣ Load capacity of each main beam | 40T |

| ♣ Maximum lifting force per column | 40T |

| ♣ Weight of each main beam | 5T |

| ♣ Weight of each lifting unit | 3.5T |

| ♣ Weight of trolley | 0.5T |

| ♣ Span | 12m |

| ♣ Lifting stroke | 2m-3.5m |

| ♣ Number of jacking units | 2pcs |

| ♣ Lifting/falling speed | 0-1 m/min |

| ♣ Trolley (lifting point) moving speed | 0-5 m/min |

| ♣ Gantry moving speed | 0-10 m/min |

| ♣ Crane power system | Electric power, hydraulic system |

| ♣ Control mode | Remote control operation |

| ♣ Working pressure | 20-25Mpa |

| ♣ Working environment | -10℃~+40℃ |

| ♣ Power supply | 380v 50hz 3P |