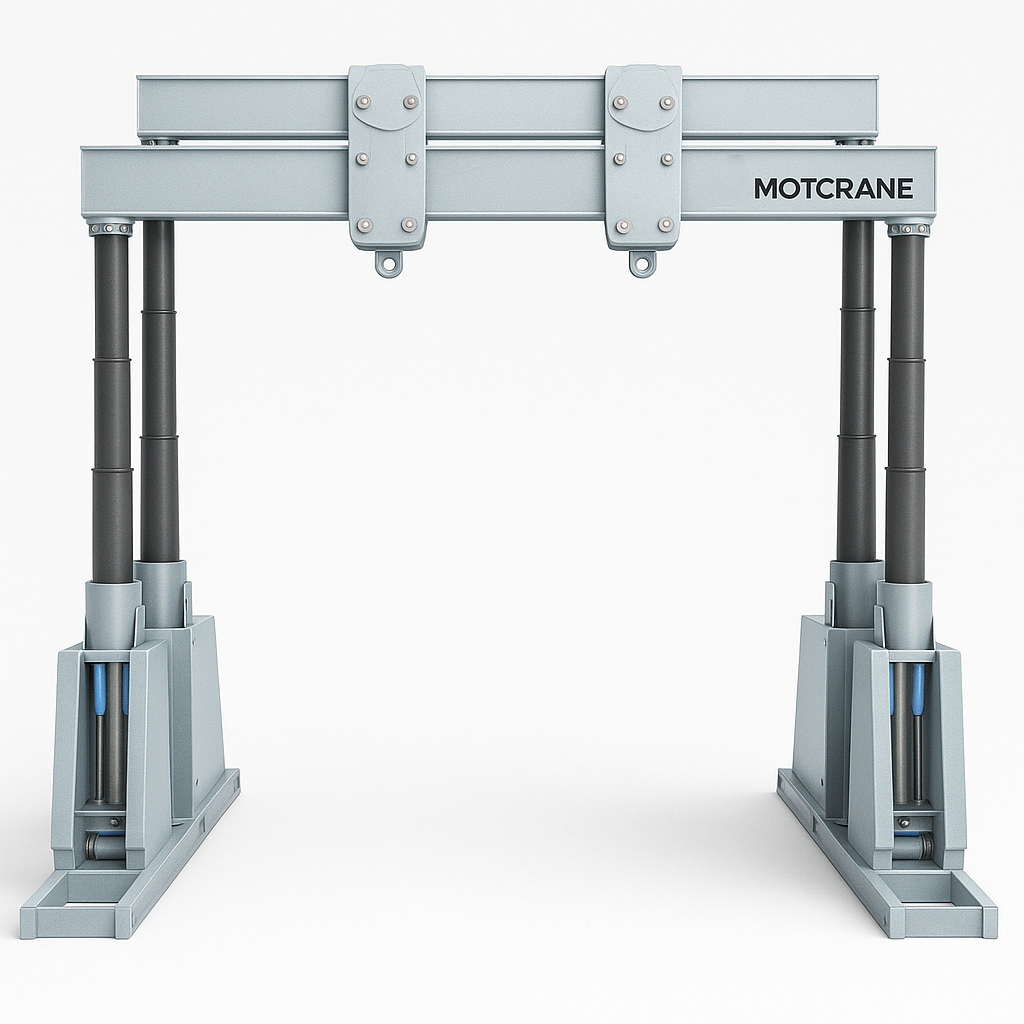

Hydraulic Gantry Crane Selection & Applications (≤100 t)

— 20 t / 30 t / 60 t / 100 t

1) Engineering Positioning (and why it’s not a conventional gantry)

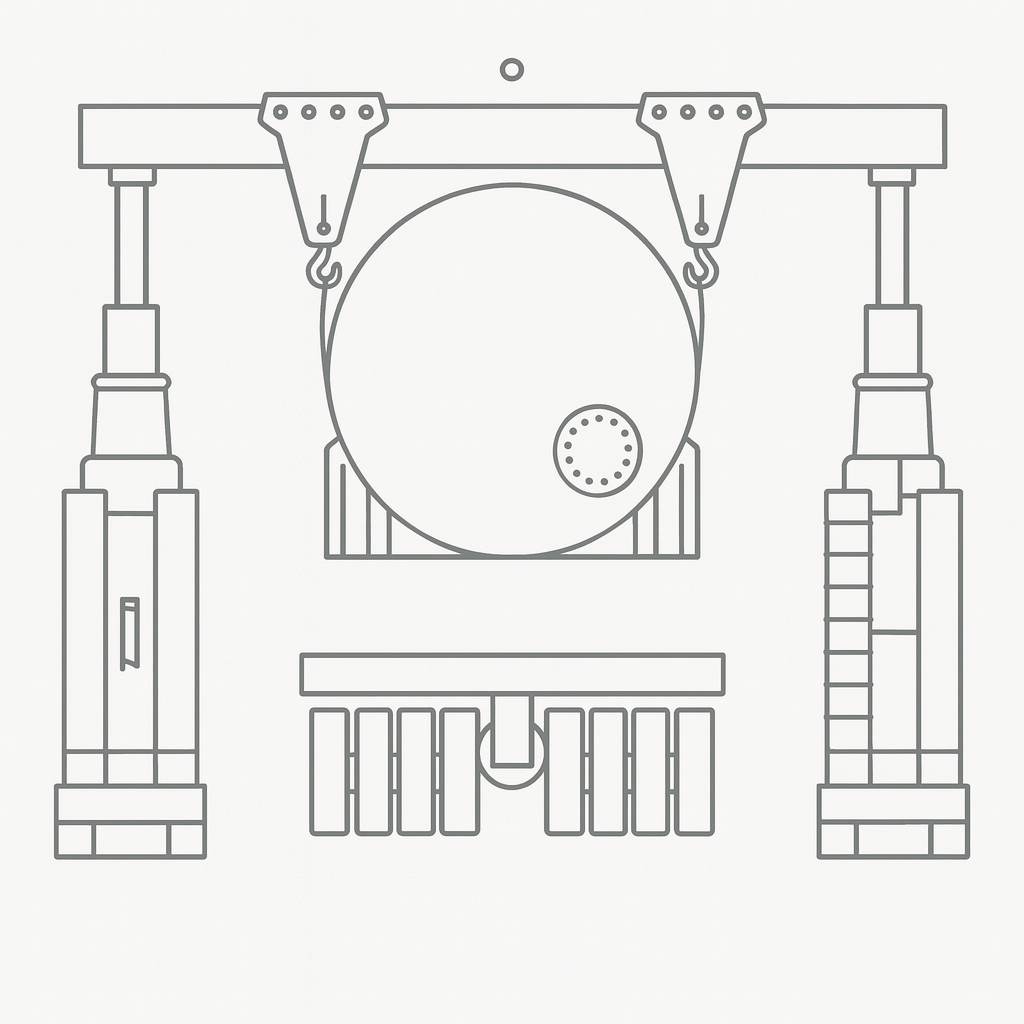

A Hydraulic Gantry Crane is an installation-grade lifting system purpose-built for space-constrained, low-headroom environments and high-value equipment that must be precisely set in place.

Core characteristics:

♣ Self-supporting hydraulic legs with telescopic columns — no runway beams or fixed rail required; works on slabs or temporary foundations.

♣ Multi-cylinder synchronized lifting — controlled vertical travel and micro-motion for millimeter-level alignment (sensor & control package dependent).

♣ Modular logistics — legs and header beams split for easy transport and fast site access/exit.

♣ Low-headroom fit — completes installation workstations where bridge cranes or mobile cranes cannot reach.

Think of it as an installation platform rather than a material-handling gantry: it prioritizes placement accuracy and site adaptability, not long-run repetitive travel.

2) Tonnage vs. Use-Case Mapping (20 t / 30 t / 60 t / 100 t)

♣ 20t hydraulic gantry crane— Precision equipment installs / maintenance bays

Typical tasks: CNC machines, molds, hydraulic presses, test benches; tight indoor aisles and doorways.

Why 20 t: Small footprint, agile layout changes; ideal when regular loads are 8–15 t with reasonable reserve.

♣ 30t hydraulic gantry crane— The “universal” mid-range

Typical tasks: Medium injection/press machines, diesel engines, propellers, welded steel fabrications.

Why 30 t: Broad coverage while remaining maneuverable; often the first choice for mid-size plants.

♣ 60t hydraulic gantry crane— Workhorse for heavy manufacturing & line relocation

Typical tasks: Large presses/cell equipment, boilers/heat exchangers, medium generator sets; modular line moves.

Why 60 t: Comfortable with 40–50 t regular loads; balanced lift height and capacity for reliability and takt time.

♣ 100t hydraulic gantry crane— Insurance for critical assets and special workstations

Typical tasks: Power transformers, precast bridge elements, large marine/engine modules.

Why 100 t: Higher safety margin and adaptability where low headroom + high tonnage + precision set-down converge.

3) How to Choose (engineering checklist)

♣ Max load × safety factor

Size by max workpiece mass × 1.2–1.3. (Example: 50 t ⇒ select 60 t model.)

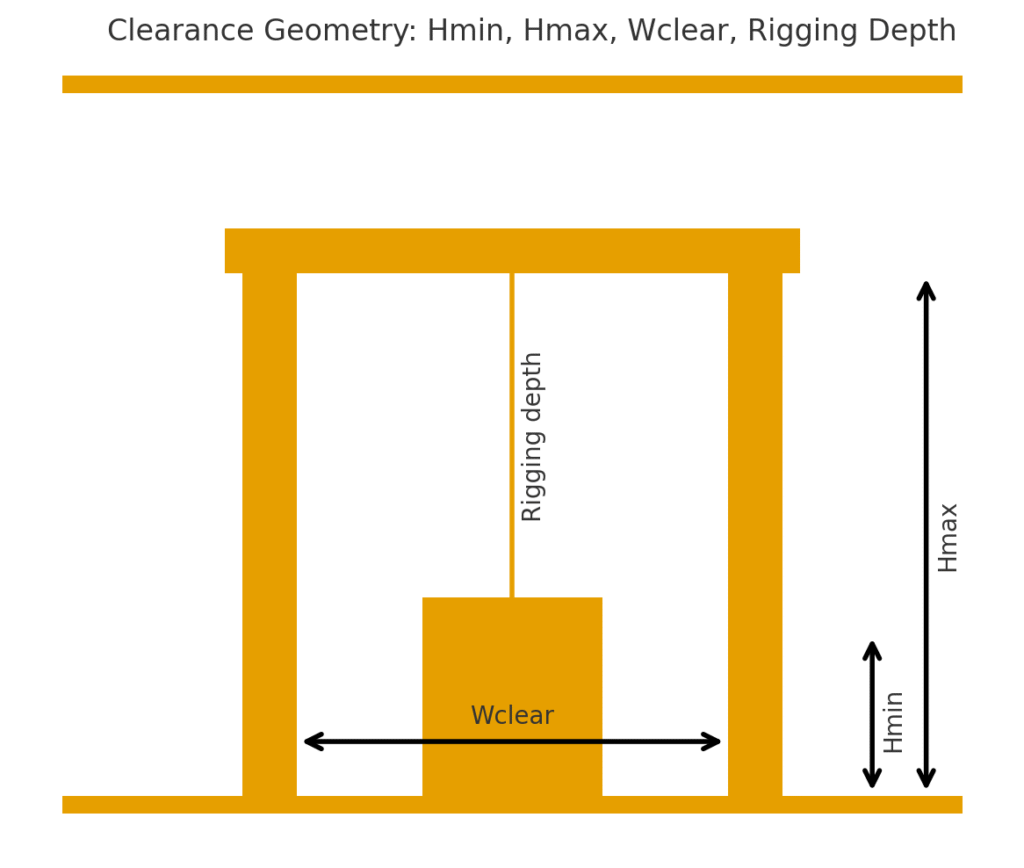

♣ Geometry & clearances

Column retracted height + workpiece height + rigging depth + safety allowance (commonly ≥200–300 mm). Consider low-headroom beams if tight.

♣ Ground bearing & load path

Compute bearing pressure and use outrigger mats/steel plates to spread load; add factors for turns, joints, ramps.

♣ Synchronization & placement accuracy

Verify multi-point sync (displacement/pressure feedback), micro-speed control, mechanical locking (anti-drop/self-lock).

♣ Project takt & mobility

Multi-site project work favors modular, fast setup/teardown; fixed stations may add rollers/slide shoes for short horizontal moves.

♣ Lifting points & CG

Confirm center of gravity, padeye strength, and rigging match (spreader beams, slings, chains). Long parts benefit from a tailored spreader to limit deflection and sway.

4) Typical Configuration Blocks (customizable)

♣ Hydraulics: proportional/servo valves, relief & hold circuits, counterbalance valves, optional EX-proof.

♣ Sync control: 4-point/multi-point, linear displacement sensors (draw-wire/LVDT) and pressure/load monitoring.

♣ Locking & safety: mechanical lock sleeves or rack-type anti-fall, overload/travel/tilt alarms, E-stop.

♣ HMI & power: wired/wireless remote console; real-time height/position/load display; diagnostics; 3-phase 380/400/415/440/460 V 50/60 Hz.

♣ Beams & accessories: modular header beams, side-shift device, rollers/slide shoes, temporary rails, outrigger mats.

5) Ground-Bearing & Stability (what to check)

♣ Slab/foundation design values: concrete grade, thickness, reinforcement, sub-base compaction.

♣ Bearing pressure: total load ÷ effective contact area; increase area with mats/plates when needed.

♣ Lateral stability: include side-shift/wind/acceleration loads; check height-to-base ratio and friction coefficient.

♣ Route planning: inspect joints, potholes, slopes, turning radii; mark exclusion zones before the lift.

6) Quick RFI / Inquiry Checklist (send these for a fast proposal)

♣ Max & regular weight (t) and CG position/tolerance

♣ Workpiece envelope (L×W×H) and padeye positions/strength

♣ Site clearances (min headroom, clear inside width, access openings)

♣ Target set-down height (foundation/equipment base + tooling allowance)

♣ Ground data (build-up details or allowable bearing values)

♣ Operation cadence (annual/seasonal/monthly frequency; multi-site?)

♣ Power & environment (voltage, EX, low-temp, corrosion)

♣ Delivery window & service (install/commissioning/training as needed)

7) Why MOTCRANE

♣ Coverage: 20 t / 30 t / 60 t / 100 t ready-to-adapt solutions; non-standard engineering on request.

♣ Engineering deliverables: load & stability checks plus ground-bearing recommendations.

♣ Controls & safety: multi-point sync, displacement/load monitoring, mechanical self-lock/anti-fall, E-stop.

♣ Delivery & service: rapid build, global install/commissioning/training, reliable spare-parts support.

Call to Action

Working in low headroom or tight spaces and need precision set-down for high-value equipment?

Send MOTCRANE the Inquiry Checklist above. We’ll return two practical options (standard configuration vs. upgrade-ready) with budget ranges to match your project plan.