ورشة الهياكل الفولاذية ورافعات EOT المصدرة إلى العميل الإثيوبي، يعتزم العميل تركيب مجموعتين من رافعات EOT أحادية العارضة في ورشة صيانة محركات الطائرات الحالية لتفكيك وتجميع المحركات. ومع ذلك، فإن هيكل مبنى المصنع الحالي لا يتمتع بقدرة تحمل كافية لتلبية متطلبات تركيب رافعتين أحاديتَي العارضة EOT، كما أن ارتفاع خلوص الورشة منخفض للغاية.

ولذلك، طلب العميل مساعدتنا في تصميم ورشة عمل جديدة للهيكل الصلب ورافعات EOT المصدرة إلى إثيوبيا. (جهاز واحد و رافعات EOT مزدوجة الجيردر المزدوج).

نظرًا لعدم كفاية قدرة التحميل غير الكافية لورشة الهيكل الفولاذي الأصلي، فمن المستحيل تركيب رافعة EOT. لهذا، هناك أمران ممكنان الحلول:

1. إضافة أعمدة جديدة بجانب الأعمدة الداخلية لمبنى المصنع لدعم الرافعة العلوية. إذا كان ارتفاع مبنى المصنع الحالي لا يفي بمتطلبات الاستخدام، فمن الضروري أيضًا إجراء معالجة ارتفاع مبنى المصنع في وقت واحد.

2. هدم مباني المصنع الأصلية وإعادة بنائها.

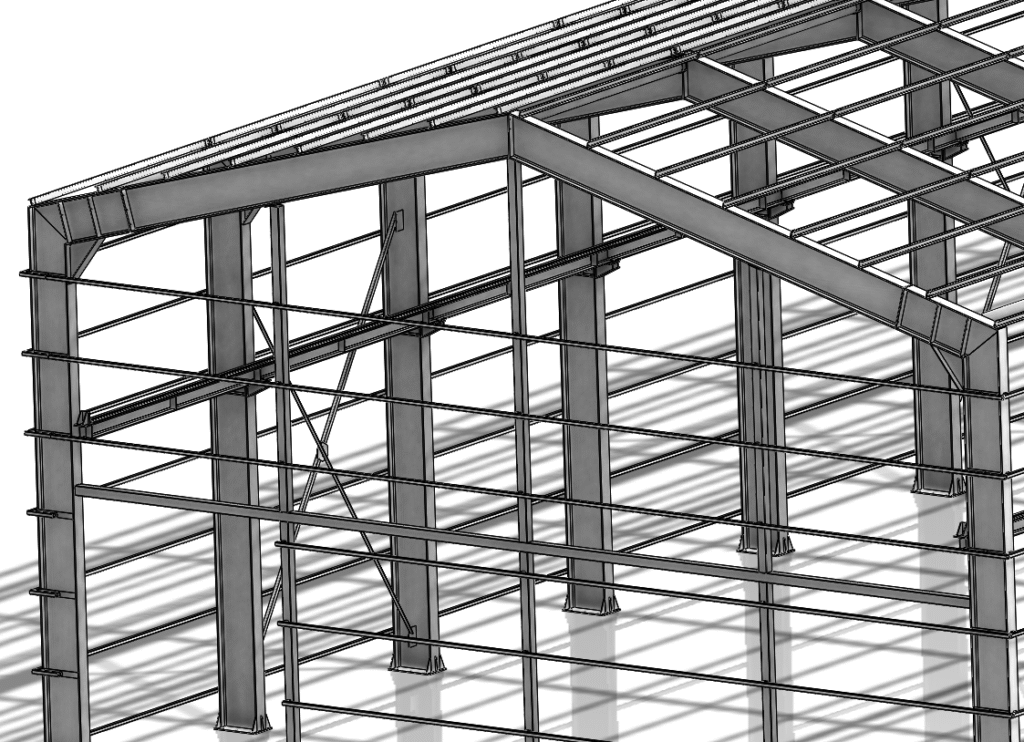

لقد صممنا ورشة الهياكل الفولاذية بناءً على الحمولة القصوى لرافعتين EOT (رافعات كهربائية متحركة علوية متحركة). يجب أن يتوافق تصميم الهياكل الفولاذية الصناعية مع معايير الصناعة والمعايير الدولية ذات الصلة لضمان سلامة وموثوقية الهيكل.

تتألف الهياكل الفولاذية عادةً من مكونات مثل العوارض الفولاذية والأعمدة والدعامات القطرية والدعامات الفولاذية، وموادها الرئيسية هي الفولاذ الإنشائي الكربوني من نوع Q235B أو Q345B المطابق للمعايير الوطنية.

تعتمد رافعة EOT على هيكل مزدوج العارضة. ستتعامل الرافعة مع الأحمال التي تبلغ في المتوسط 50 في المائة من السعة المقدرة مع 5 إلى 10 رافعات في الساعة. ووفقًا لمتطلبات العميل، سيتم تركيب ثلاث آليات رفع (2*6 طن + 1*2 طن) على العارضة الرئيسية. المتطلبات الفنية المحددة لآليات الرفع (رافعات كهربائية) هي كما يلي:

يجب أن تكون جميع الرافعات مدفوعة كهربائيًا وتحتوي على حبل سلكي مزود بأسطوانات مقطوعة آليًا ومفاتيح حد الرفع العلوي والسفلي.

محرك المحرك:يجب أن يطور محرك الرافعة قدرة كافية لرفع الحمل المقدر بالسرعة المحددة. يجب أن تكون جميع المحركات محمية من السخونة الزائدة بواسطة واقيات حرارية.

التروس:يجب أن تكون جميع التروس مصنوعة من مواد ذات قوة ومتانة كافية لتلبية المتطلبات

يجب ألا يتطلب زيت تشحيم التروس الاستبدال طوال العمر الافتراضي العادي للرافعة.

طبل الحبل:يجب أن تكون الأسطوانة مدعومة من كل طرف بمحامل مانعة للاحتكاك محكمة الغلق.

دليل الحبال والأسطوانة:يجب أن يكون حبل الرفع ذو تصميم وبنية مناسبة لخدمة الرافعة. ولضمان اللف الإيجابي للحبل على الأسطوانة ولمنع تداخل الحبل والتلامس المحتمل أن يكون خطيرًا في ذروة الأخدود، يجب استخدام موجه حبل الرفع. يجب عدم السماح بلف الحبل

مفتاح التحديد:يجب أن يكون الجسر والعربة مزودين بمفتاح حد، ويجب أن يكون هذا المفتاح قابلاً للتعديل لضبط الحدود القصوى العليا والدنيا لمحركات القيادة.

| المواصفات | EOT CRANE 5T | EOT CRANE 14T | ورشة عمل الهياكل الفولاذية |

| ♦ سعة التحميل : | 5T | 2*6 ت+2 ت | الطول : 65.9 م |

| ♦ ارتفاع الرفع : | 7m | 7m | الارتفاع : 15 م |

| ♦ الامتداد : | 21.5m | 21.5m | العرض : 24 م |

| ♦ الطبقة العاملة::الطبقة العاملة | 2م/م5 | 2م/م5 | |

| ♦ سرعة الرفع : سرعة الرفع : | 5/0.8 م/دقيقة | 5/0.8 م/دقيقة | |

| ♦ سرعة حركة الرافعة : | 0-20 م/دقيقة | 0-20 م/دقيقة | |

| ♦ وضع التحكم : وضع التحكم | جهاز التحكم عن بُعد | جهاز التحكم عن بُعد | |

| ♦ مصدر الطاقة : | 3 فولت 380 فولت 50 هرتز | 3 فولت 380 فولت 50 هرتز | |

| ♦ لون الرافعة الكهربائية : | أحمر | أحمر | الرمادي |

ورشة عمل الرسم(انقر للتحميل) 2020-01-01